THIS IS A RECLAIMED 206 SHORT BLOCK

There are probably thousands of 206 engines sittng on the shelves of garages in the USA. Many of them deemed illegal because Briggs came out with new and improved block seals. They may be dirty but other than that most of them are still in excellent mechanical condition. Often times the cylinder can be honed and still be with in tolerance for a new stock size domed high compression piston. They can be faster after honing since they will now have a straight bore with just a little more clearance to loosen them up!

This short block block includes a very good clean block, a very good spec crankshaft, measured with a micrometer, key ways inspected, good threads for the clutch and flywheel, new ARC billet rod with bearing inserts, new domed piston and rings, and a new wrist pin and clips. It also includes a crankcase cover / side cover.

Feel free to give me a call at 920-207-9180 if you have questions!

The cylinder will be honed with a rigid hone to make sure it is straight, round and true! A new Standard size, or a .005" or .010" oversize Domed Piston and rings will be fitted to the cylinder with proper clearance! I also have a .020" oversize piston but very rarely need to use one that big. The crankshaft is also measured with a micrometer to make sure it is in excellent condition.

Another option is if you have a complete 206 engine that yuou would like to make into a Super Stock you can send it to me. Or if you like you can send me just the block. I'll look it over and I'll and give you a call back about it!

For those that want to create a class at their home track here are the rules you can use.

206 SUPER STOCK RULES

The spirit and intent of this engine package is designed to make use of LO 206 Briggs engines that have become tired, worn or in any other way un-useable for the LO 206 class.

It is also an inexpensive way to go faster than a stock LO 206.

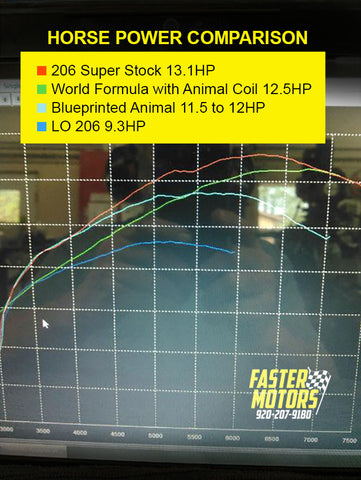

It makes about 40% more Horsepower than a senior LO 206.

These changes will allow you to inexpensively convert a tired engine that you already have sitting on the shelf into an engine with more power and give you several more years of use.

Examples of salvageable engines would include engines that were run without oil or engines that have other worn internal parts. Engines that have worn piston or rings make excellent candidates for the 206 Super Stock.

The only changes you will be allowed to make to the block will be to hone the cylinder slightly and use a standard bore, a .005”, a .010” or a.020” oversize specified domed piston. If you can’t hone the cylinder yourself there are lots of kart shops or automotive machine shops that can do this for you inexpensively.

* Faster motors will gladly hone your worn cylinder as well!

ALL PARTS ARE TO BE ORIGINAL BRIGGS & STRATTON 206 PARTS UNLESS SPECIFIED OTHERWISE.

THE CURRENT BRIGGS & STRATTON 206 RULE SET WILL BE USED FOR ALL ENGINE RULES AND SPECIFICATIONS EXCEPT FOR THOSE LISTED BELOW.

THE 206 RULES CAN BE FOUND ON THE BRIGGS RACING WEBSITE.

A FEW EXAMPLES OF THE EXCEPTIONS TO THE BRIGGS 206 RULES WOULD BE FOR THE METHANOL CARBURETOR JETS AND NOZZLE, THE CAMSHAFT, THE CONNECTING ROD AND THE DOMED PISTON. (THE COMPLETE LIST CAN BE FOUND BELOW.)

YOU ARE ALLOWED TO HONE THE BORE AREA OF THE CYLINDER TO FIT A NEW APPROVED DOMED PISTON. YOU ARE NOT ALLOWED TO MACHINE THE CYLINDER BLOCK IN ANY OTHER WAY! YOU ARE NOT ALLOWED TO MACHINE THE CYLINDER HEAD, CARB, FLYWHEEL, OR ANY OTHER PART OF THE ENGINE !!

IF IT DOESN’T SPECIFICALLY SAY YOU CAN DO IT THEN YOU CAN’T !!!

Starting Must be pull start. Must use the OEM Briggs recoil starter!! The Briggs compression release must be intact and operational. It it is not the motor must be disassembled and checked for the compression release. No electric starters Allowed!!

If the motor turns over very had with the recoil it may indicate that the cam does not have a compression release on it At the discretion of the tech official

Block

LO 206 blocks are the only block permitted. They can be identified by the appropriate numbering on the front of the block adjacent to the drain plug. The crankcase cover dowel pins must also have been drilled for the seals.

Decking of the block is not permitted and the factory machining marks must be present on the deck surface. Must be part number 555705 or equivalent. No Intek blocks allowed. Absolutely no welding of the block. If you need to repair a hole in the block from a broken rod you must use Epoxy. No welding of the internal or external cylinder area is allowed. Replacing the cylinder sleeve is not legal. The cam bearings must remain original. No other bearing design is legal. Welding anywhere inside the block is illegal. The crankshaft bearing pocket must remain in factory condition.

No Modification of the bearing pocket is allowed.

The oil return hole between the lifter bores must not be larger than .2055”

Any bolt hole may be repaired with a helicoil of original size. The repair must not create a performance advantage.

Holes for the air shield may use the next size larger bolt.

Holes for the blower housing may be repaired with a helicoil of the original size.

Magnetic drain plugs are legal. A cracked block in the drain plug area may be repaired by epoxy and by installing a short piece of ¼” pipe 1” long.

No block supports of any kind are allowed.

The camshaft bearing must remain completely stock. No welding.

No painting of the block, head side cover or carb is allowed. You may paint the blower housing, control cover or air shield.

Piston

Must be a domed piston with DED engraved in it. The piston is non directional so the DED engraving can be at the top or bottom side of the piston. The piston must be one of these sizes STD or .005, .010 or .020 inches oversize. There is no advantage to using a .020" oversize piston. It just allow for extended use of the blocks. Maximum cylinder bore is 2.710”

Gaskets and Seals

All gaskets and seals must be OEM Briggs parts.

Briggs fire ring head gasket Part number 555698 is required. Minimum thickness is .042”

Camshaft

The only legal camshaft is the AN Mod 1 Dyno cam. It must be the cast welded version with the compression release !! The Tool Steel Billet version is not allowed !! The lift must be between .307” and .311” when measured at the push rod. The lift at the valve retainer must be between .305” and .313” when measured at the valve retainer with negative .002 valve clearance.

Profile

Intake Exhaust

Open: 57.15 BTDC 96.10 BBDC

Close: 95.30 ABDC 57.95 ATDC

Lift: .309" .309"

C/L: 108.0 ATDC 108.0 BTDC

DUR @ 50: 255.00 Deg 259.95 Deg

Valve Springs

Must be Faster Motors dual springs. To prevent damage to the compression release you must reduce the valve spring pressure on the exhaust valve. To do this you must remove the inner spring of the dual spring set and discard it. Failure to do so is illegal and may result in breaking the compression release lever on the exhaust cam lobe. If the compression release breaks pull starting the engine will be very difficult and may result in injury to your hand, arm or shoulder. This set up has been track tested by hundreds of people that have purchased the super stock kit! The engine runs flawlessly this way. The exhaust valve is much smaller and lighter than the intake valve, so there is no need for the additional spring pressure. You must use the dual springs on the larger and heavier intake valve.

Crankshaft

Must be Briggs part number 557137. It must be in completely original condition. No modifications allowed. It may not be lightened in any way. No grinding of any kind is allowed. No clearancing of any of the bearing surfaces is allowed.

The bearing surface of the crankshaft for the flywheel side bearing must be no smaller than .873”

The bearing surface of the crankshaft for the PTO side must not be any smaller than 1.061”

The crankshaft connecting rod journal must not be any smaller than 1.096”

Crankshaft Bearings

Must be OEM Briggs part number 798538 for the PTO side and 690824 for the flywheel side. If the bearing numbers are superseded to a different number that will be acceptable.

No Aftermarket or ceramic bearings allowed.

Crankshaft End Play

Crankshaft endplay will be measured with a dial indicator and must not exceed .015” at any temperature.

PTO Bearing

The OD of the PTO bearing must be 2.046 Minimum

The ID of the PTO bearing must be 1.063 Max

The PTO crankshaft bearing must be a press fit into the side cover.

Flywheel Side Crankshaft Bearing

Must not have an outside diameter smaller than 1.850 inches and an inside diameter larger that .8755 inches. The bearing should be a slip fit into the block. You can not locktite the bearing into the block or knurl or pin punch the block to tighten the fit into the block.

Crankshaft Keys

Must be OEM Briggs part number 798972 for the PTO side and 690959 or the flywheel side. See the LO 206 rule book for more specifications on the flywheel key.

No offset keys allowed. The ignition timing must be between 26 and 30 degrees. It will be measured using a piston stop and a degree wheel.

Crankshaft Gear

Must be OEM Briggs part number 695087

Cylinder Bore for any engine cannot exceed 2.710” at any point.

The bore must have conventional hone marks and cannot have any circular grooving at any point in the cylinder.

No plating such as Nickosil or anti friction coatings of any kind will be allowed.

Side Cover

The stock side cover is required. Part number 555706 is the only legal part.

No billet side covers are allowed. The crankshaft bearing and bearing pocket must remain stock. No welding or epoxy of the side cover is allowed.

Mo machining or grinding of either the bearing or bearing pocket is allowed. The crankshaft ball bearing must be a press fit into the side cover.

The oil fill caps must be original equipment. No aluminum oil fill caps allowed.

The cam bearing must remain stock. No welding of the side cover is allowed.

Stripped bolt holes may be repaired with a helicoil of original size.

PTO bearing pocket cannot be machined in any way and must not be larger than 2.047”

Flywheel side bearing pocket cannot be machined in any way and must not be larger than 1.855”

Connecting Rod

Must be the Briggs World Formula rod part number 557117 or ARC 6249 rod.

The length of the rod from the bottom of the wristpin hole to the top of the connecting rod hole is 2.419” to 2.429”

The oil hole in the World Formula rod cannot exceed 0.185”

Lifters

Must be OEM Briggs part number 690977. No aftermarket lifters allowed.

The head diameter must be between .820” and .860”

The length must be 1.515” and 1.525”

The lifter surface must be flat. It can not be concave or convex.

Measure with a depth micrometer and also with a straight edge.

Stroke

May not exceed 2.204”

Piston

The specified Domed pistons are the only pistons allowed.

The piston sizes allowed are Standard, .005”, .010” and .020”oversize.

The pistons are available from Faster Motors and other shops and program supporters.

The distance from the top of the piston to the top of the wrist pin must be between .870 and .875"

Piston pop up measured from the top of the block deck surface to the top of the dome of the piston shall not exceed .110” when measured parallel to the wrist pin and also at 90 degrees to the wrist pin.

Piston Rings

You must use all three rings. They must be OEM Briggs part number 555664 (std) or 555665 (.010” oversize) or 555666 (.020” oversize)

No modifications to the rings allowed except filing for end gap. Recommended end gap by Briggs for the top ring is .004”

All the rings must be intact when the piston is removed from the engine. An engine with a broken ring will be disqualified.

The rings cannot be heat treated or shrunk in any way.

When rings are removed from the piston they must be self supporting in the cylinder.

The dot on the top two rings must be facing up.

The chamfer on the ID of the second ring must be facing down.

Minimum width for either of the top two rings is 0.096”

The thickness of the top two rings must be between 0.060” to 0.062”

The oil ring expander cannot be shortened.

The length of the oil ring expander for the std piston must not be less than 8.200”

The oil ring expander for the .010” oversize piston may not be less than 8.250”

Piston Pin must be OEM wrist pin part number 499423. The dimensions for the wrist pin must be as follows:

Outside diameter must be between .624” and .626”

Inside diameter at the outer ends must not be larger than .414”

The length must not exceed 1.762” It must not be shorter than 1.903”

Carburetor Methanol

The PZ carburetor is the only legal carb. All LO 206 rules apply except for the main jet , the

idle jet and the main nozzle.

Main Nozzle size:. .104” gauge must go but a .107" gauge must not go.

Main jet size: .054” gauge must go but a .057” gauge must not go.

Idle Jet size: .014” gauge must go but a .017’ gauge must not go.

You may use the appropriate parts from the Briggs methanol jet kit 555537.

You can make your own jets but they must conform to the rules!

The .602” carb measurement is of particular importance and will be checked frequently!!

All other carb rules are the same as the current LO 206 rules.

You must use pure methanol for fuel. It will be tested according to existing kart racing standards and procedures.

NO additives will be allowed.

Carburetor Gasoline

Must follow the existing LO 206 rules.

Suggested fuel is 93 octane pump gas. Hint if the fuel is red or blue or any other color than normal pump gas it is probably higher octane and oxygen enriched fuel and is illegal.

Ignition Coil

Must be the Briggs Blue colored PVL ignition coil Part Number 555681 or 557125 red World formula coil depending on the rules for you decide on for your track or event.

Flywheel

You must use the Briggs PVL flywheel Part Number 555683 and plastic flywheel fan part number 692592

Spark Plug

Must be Champion RC9YC or RC12YC with the OEM sealing washer / gasket installed.

Air Filter

The unaltered LO 206 air filter is legal as well as a less expensive unaltered aftermarket air filter with the following dimensions 3" x 4" (1.25" I.D.) A nylon prefilter is legal. Oiling the actual air filter is also legal and encouraged. Be prepared to remove the prefilter for inspection prior to any practice, heat race, or final / feature race.

The use of any air filter that has the internal portion radiused, ground, chamfered or machined, is illegal. Anything that resembles modification internally will be illegal. There should be a sharp edge inside the air filter that can be felt with your finger.

Below is an example of a legal inexpensive after market legal air filter.

Cylinder Head

The RT 1 cylinder head is the only legal head. The use of the Briggs heat disperser is allowed Part

number 555690. It may be added to older production RT 1 heads.

The heat disperser is not required but is definitely encouraged!!

See LO 206 rules for additional specifications.

Oil

Briggs & Stratton 4T Racing oil is highly recommended

Fuel

Methanol is the preferred fuel. It must be pure methanol with NO additives. No top engine lube will be allowed. Generic methanol works great! It’s ½ the price of the price of “racing fuel”

and works just as well.

To be legal fuel must pass a hydrometer test and or Digitron test.

Gasoline

If gasoline is used it should be 91 octane pump gas. Using fuel with a higher octane is not necessary nor allowed. Hint, If it’s some other color than normal pump gas that’s a dead give away that it’s not standard pump gas

Other engine parts such as the exhaust pipe and muffler will follow the existing LO 206 rules!

Other examples that will follow the 206 rule book are the ignition timing, flywheel weight and fuel pump etc will follow the existing LO 206 rules!

Any part numbers given herein that is superseded by Briggs & Stratton in the future will be acceptable.

CLUTCH - Any clutch approved clutch found in the Briggs & Stratton rule set is legal. Any other clutch is not legal! EXAMPLE Disc clutches or any other variation is not allowed!

THE CURRENT 206 RULE SET WILL BE USED FOR ALL OTHER ENGINE SPECIFICATIONS !!!

EXAMPLES WOULD BE FOR THE CARBURETOR MEASUREMENTS (EXCLUDING METHANOL JETS AND NOZZLE) ALL THE CYLINDER HEAD MEASUREMENTS, IGNITION TIMING, FLYWHEEL SPECIFICATIONS, STROKE, EXHAUST PIPE AND MUFFLER / SILENCER SPECIFICATIONS, NO TAPE OR SIMILAR MATERIAL ON THE BLOWER HOUSING OR RECOIL STARTER.

206 SUPER STOCK RULES (UPDATED 2/8/2022)